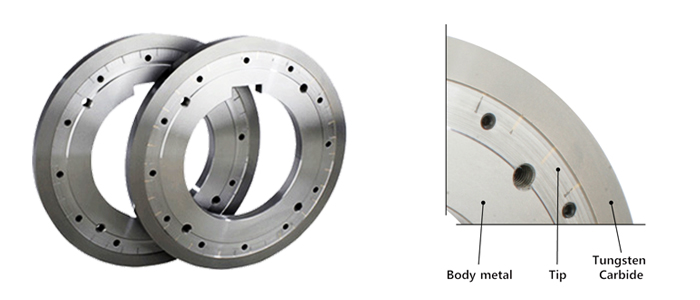

Brazing Tungsten Carbide Knife

Steel knives made of tungsten carbide are mostly used for slitting and side trimming sheets. They have significantly higher wear resistance and rigidity compared to regular tooling steels for a longer lifespan.

The regular solid-type tungsten carbide knives are weak against shock, highly likely to break, and large and heavy to cause various accidents. Also, they are too expensive to apply to various lines.

DAE WON IN MUL Co., Ltd. has developed the brazing-type tungsten carbide knives that have resolved all of these drawbacks and applied them to various lines.

- Characteristics

- The shock-absorbing design is strong against shock to prevent breaking when cutting cold-rolled high-strength sheets.

- The combination of tungsten carbide and a special steel that is lighter than tungsten carbide makes it lighter to place less burden on workers' muscles and bones and lower the load on the facilities.

- The brazing-type tungsten carbide knives are economical to use at various lines as they are made with the minimal amount of expensive tungsten carbide.

- Applications

- Slitter Knife, Side Trimmer Knife

- Places of use

- Cold-rolling plants, stainless steel plants, electrical steel plants, hot melt galvanizing plants, etc

- Suitable for cutting

- Regular steels, high-tension steels, high-carbon steels, stainless steel, and other high-strength steels