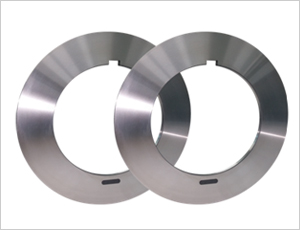

Dry lubricant coating

This coating was developed for surface lubricating to prevent the migration of debris of materials being cut when cutting soft steels such as aluminum with knives for steels. It has significantly reduced the coefficient of friction to resolve any problems caused by the wearing and friction of parts and improve quality and productivity.

- Characteristics

- The smallest coefficient of friction among the lubricating materials

applied to solid materials: 0.03~0.09 - Thin coating: 0.5㎛ or thinner

- Low working temperature: Room temperature

- Broad range of temperature: -270 to 700℃

- High pressure resistance: 1000 to 2460kg/cm²

- Use

- Used to coat parts that require high precision and lubrication.

- Knives, press molds, extrusion molds, cutting tools, bearings, joints, etc

- Parts for aviation industry and space industry

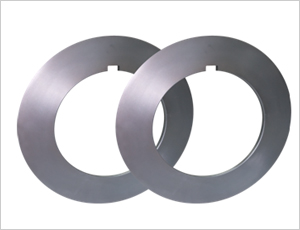

Corrosion-resistance coating

Developed to prevent the corrosion and rusting of knives for cutting work or storage.

- Characteristics

- Thin coating: 1㎛ or thinner

- Low working temperature: Room temperature

- High heat resistance: 700℃

- Forms a hard coating surface.

- Use

- Prevents the corrosion of knives by moisture and salinity in the

cutting process exposed to high humidity. - Prevents the corrosion of knives by acids in the cutting process at

pickling plants, etc. - Prevents the corrosion of parts by various causes.